In Bagel Bytes Robotics, there are 7 subteams: Manufacturing, Design & Assembly, Programming & Control Systems, CAD, Business, Strategy/Scouting, and Safety, and then there is the Team Captain that oversees each subteam.

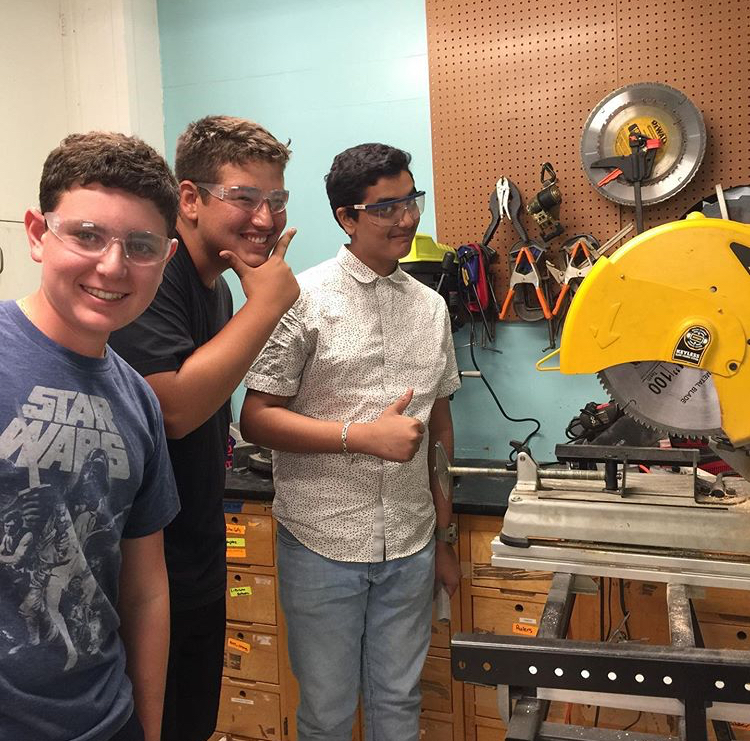

Manufacturing

The manufacturing subteam performs all tasks and duties in regards to the creation of the individual parts used in prototyping and finalizing models of the machine. The functional manufactured parts demands diligence and precision, as well as a high standard of work ethic of the members of this subteam. Members work predominantly with power tools (drills, saws, motor grinders, etc.) to cut and assemble wood and metal, which is important in prototyping the robot or its field pieces.

Photo: Manufacturing includes a lot of woodworking and drilling to recreate parts of the competition field, or creating prototypes or models of the robot.

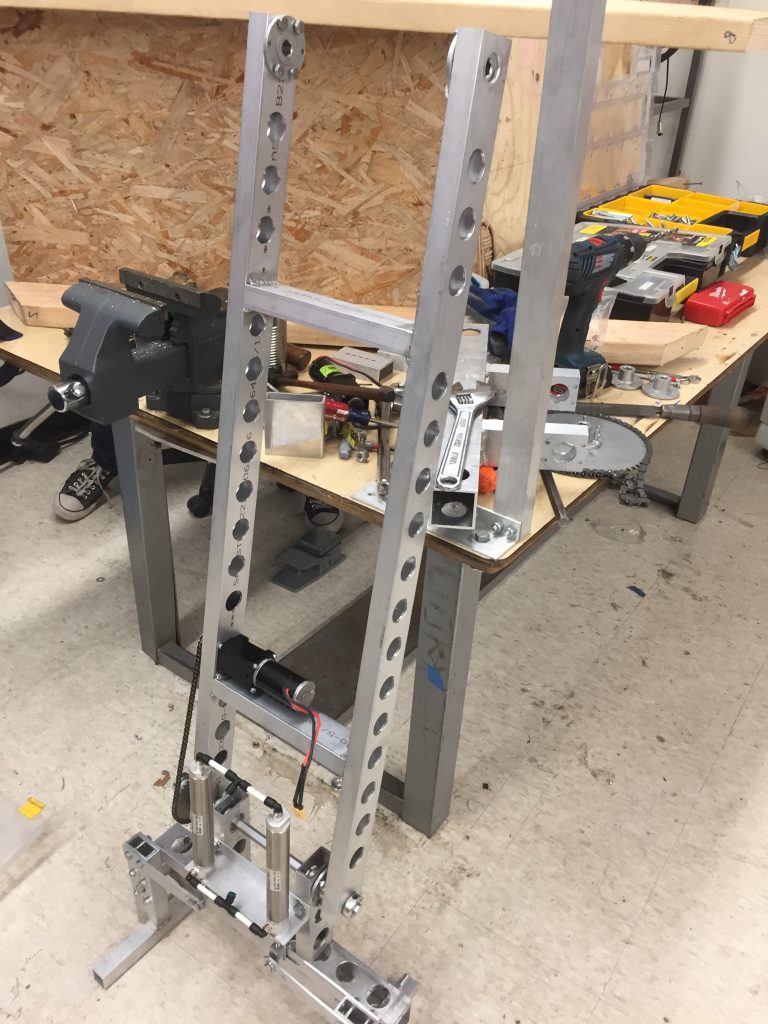

Design & Assembly

The assembly subteam is primarily in charge of the construction of the physical robot, through the assembly of the individual components crafted by the manufacturing subteam, to provide the robot an organized ‘body.’ Most assembly members will be dealing with some degree of power tools, particularly power drills, but in some aspect utilize welding (joining metal pieces or parts together by heating the surfaces to the point of melting) and hand tools to assemble the framing of the robot.

Photo: The design & assembly subteam creates the “body” of the robot after it is prototyped .

Programming &

Control Systems

The programming and control system subteam is responsible for the robot’s code (using Java) and the general functioning of the robot. The subteam codes for the robot sensors and monitors to ensure accurate readings and compliance with software programs, and allows user input to control motors on the robot. Control systems is responsible for the creation of the electronics board which is what transfers power and information through the robot.

Photo: Programming happens directly next to electronics/control systems.

CAD

CAD (Computer Aided Manufacturing) plays an integral role in the creation of the robot’s design, as it is responsible for creating virtual 3D models of any mechanisms that the team plans to build, in order to test function capability and error analysis. All changes made within the robot plans are documented by CAD, so as to ensure that all components of the robot are functional and accurate. CAD also works with the teams’ 3D printer to produce special components that improve the robot’s performance. CAD reinforces 3-Dimensional thinking, an ability to problem solve, and fosters creativity.

Photo: 3D modelling occurs on the computers through autodesk, a modeling software. These blueprints are then used directly by both manufacturing and design & assembly.

Business

The business subteam is responsible for fundraising and managing funds for the club. Communication skills are exemplified in this subteam, with members conferring with sponsors directly, by writing emails and discussing logistics. As well as compromising with subteams and agreeing on the materials that need to be bought. This subteam encourages students to learn about money management, business, and developing communications skills, and promotes students to be self-supporting in managing their own team and helps them understand the importance of management.

Photo: Part of the “sponsorship plate”, where our team gives thanks to our sponsors by putting their logos on the robot during competition

Lead Strategist

The lead strategist devises ideas to improve the way the team competes in events. This individual studies other teams’ robots and the previous season’s strategies to incorporate new and better ideas into our robot design. The job also requires analysis of the competition weaknesses and strengths so we can combat that and win.

Photo: During competition, scouts look at other teams and write their strengths and weaknesses, which is most important for choosing alliances at the end of the qualification matches.

Safety

The safety captain manages the welfare of the members of the team. This individual works alongside the subteams to make sure that everyone is safe. Additionally, in the beginning of the year, the safety captain holds a mandatory meeting to teach everyone how to be safe. If there is an accident or injury, the safety captain records it and makes sure that person gets the care they need. Once it happens the safety captain assesses the situation to make sure that it does not happen again.

Photo: Safety first! When working with power tools, our team makes sure that people wear goggles to minimize possible injuries.

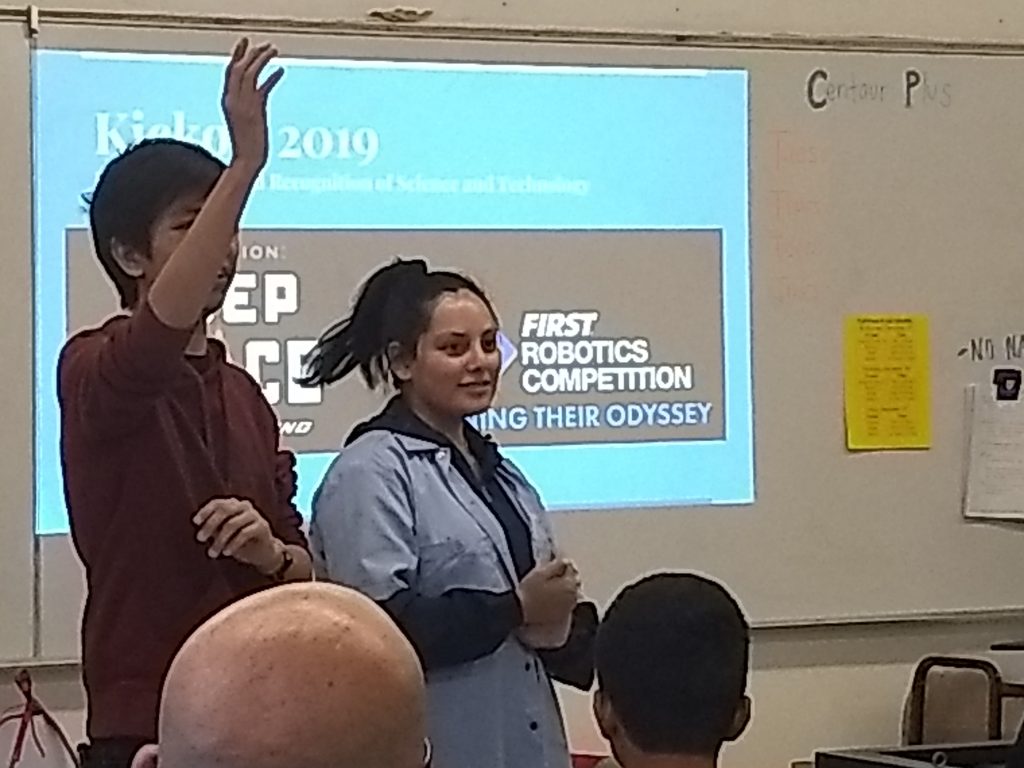

Team Captain

The team captain manages the entire team. Their job is to devise the agenda for each day. During build season the team captain constructs a schedule so every member of the team knows when he/she needs to attend Robotics and work on their part of the robot. The team captain has to be able to communicate with the subunits and has authority over the team. Additionally, the position holder bonds the team together and do all the paperwork and publicity so the team can function.

Photo: The captains manage meetings and bonds this group of students as a TEAM